Category : 8th Class

Crafts and Industries

One day while in the village on vacation, Kartic's father asked him to go to the weaver's house and bring the chaddar that he had ordered the weaver to make. When Kartic saw the weaver making cloth on a machine he was fascinated. He saw the weaver making some pattern on the cloth. It was thick and heavy. He asked the weaver, 'Can't you make a finer and smoother cloth?' The weaver smiled at him and said that once his forefathers used to make fine cloths with patterns and bright colours. Kartic wanted to ask him more questions about those cloths, the pattern and why he could not weave them now but he had to rush back home. He thought he could ask his history teacher about the weavers of earlier times.

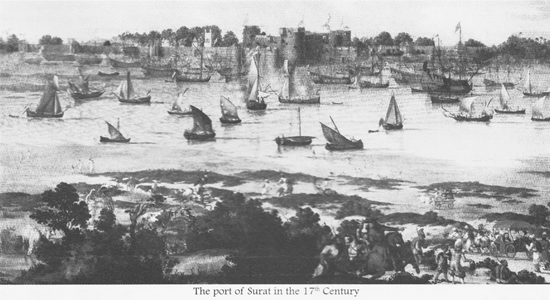

As you can see in the picture given above, Surat was an important port on the western coast of India. Also, it had important industries like textiles and iron and steel. It clearly shows that crafts and industries flourished in India before the British came to India. India was exporting its goods across the world. Indian rulers patronised crafts and large demands for handicrafts came from royal courts and urban aristocrats. Cotton from Dacca, Gujarat and Masulipatnam; the silk fabrics of Murshidabad, Lahore and Agra; woollen shawls and carpets of Agra, Lahore and Kashmir, etc., were in high demand; both in India and abroad. Indian handicrafts industry had reached a high level of excellence and enjoyed a worldwide reputation. India enjoyed extensive trade on handicrafts, within the country and with other countries of Asia and Europe. The reason for India's favourable foreign trade was its excellence in local production. Surat in Gujarat on western coast was one of the important ports of Indian

Ocean Trade.

The British initially came as traders to India. They bought Indian goods and sold them at high prices in Europe and made huge profits. However, the scenario changed with the Industrial Revolution in Britain. The British now saw India as a supplier of cheap raw materials for its industries and a market for its finished products. This had a deep impact on the Indian industries. In this chapter we will focus on the effect of colonial rule and the Industrial Revolution on Indian industries, particularly the textile and iron industry.

History Reveals

According to Robert Clive, India was a country of inexhaustible riches and the one which could not fail to make its masters the richest corporation in the world.

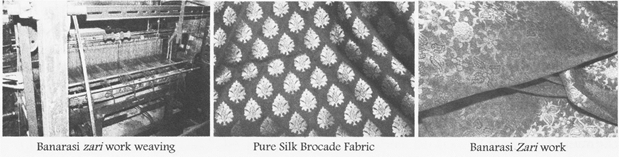

THE TEXTILE INDUSTRY IN INDIA

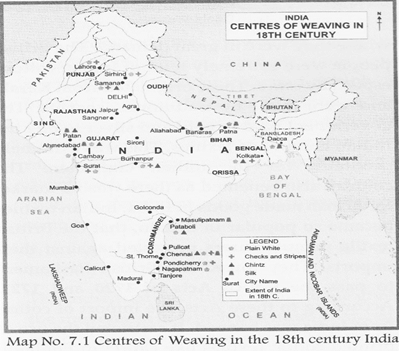

The Indian artisans were famous for their skills all over the world. Towns like?Dacca, Murshidabad, Surat, Ahmedabad, Lucknow, Chanderi, Bangalore, Aurangabad, Vishakhapatnam and Coimbatore were nourishing centres of the textile industry.

OTHER POPULAR INDIAN TEXTILES

Chintz was a brilliantly coloured cotton calico from India. It was usually printed in large, bright, colourful floral patterns.

Bandanna was a short tie-dyed silk length (also derived from the word bandhnu or banda-"to tie") from Bengal. It was an incredibly popular export in the 1700s.

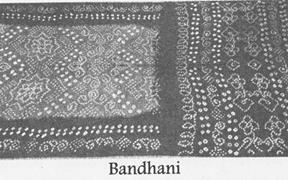

Bandhani is one of the oldest techniques which is still in use. When the East India Company first sent back textile goods from India to England, they were considered incidental to the lucrative trade of silk and spices.

Goods from India were extremely popular in Europe. Arab merchants carried cotton textiles and sold them to the Europeans. The Europeans first saw cotton in Iraq in a place called 'Mosul'. So, it came to be called as Muslin. European traders were in search of a direct trade route to India. They wanted direct trade with India and not through the Arabs.

The Portuguese were the first to find a sea route to India. Vasco da Gama reached Calicut in India in 1498. The Portuguese traded in spices, cotton, indigo, silk, saltpetre and tea. They called the cotton textiles as 'calico'.

The popularity of these vibrantly coloured and intricately patterned fabrics soon made India the greatest exporter of textiles all over the world. The height of their trade on handicrafts reached at its peak of growth in the 18th and 19th centuries.

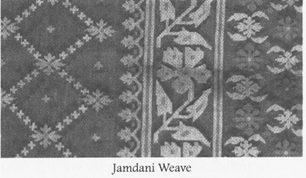

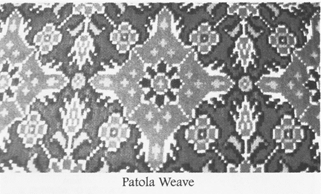

Bengal and Dacca were famous for textile production. They both had access to water transport which was widely used, as railways were not yet developed. Gujarat on the western coast was another textile producing center. Patola prints from Patan, (Gujarat) were quite famous. There were textile centres along the Coromandel Coast also.

THE EAST INDIA COMPANY AND THE INDUSTRIAL REVOLUTION

The East India Company at first concentrated on export of Indian manufactured goods like?textiles, spices, gems, etc. to Europe; where they were in great demand. The British people were extremely fond of Indian cottons especially calico. These originated from Kerala and were made by traditional weavers. The government paid in gold and silver to buy the Indian handmade textiles. This was extremely profitable for the Indian craftsmen. The country also benefited as there was no market for British made goods in India. Indian textiles became so popular in Britain that the British textile manufacturers protested against their imports. They forced the British Parliament to pass the Calico Acts of 1720 and 1721. According to these Acts, the import of cotton from India was banned. It restricted the use of printed cotton textiles like chintz in England. This was an effort to sustain the British textile industry. Even then, consumer demand for cotton products continued to grow. The British manufacturers now set up the calico printing industry. They imitated Indian designs on muslin cloth.

Q. why were the Calico Acts passed? Why were they called Calico Acts?

The British henceforth started using political power for the enhancement of their commercial and economic interest. They forced artisans and weavers to sell their goods to the Company at lower prices. This led to poverty of the artisans who had to face difficulties because they did not earn profit. Another consequence was the destruction of the market for these products as the Indian rulers and aristocracy which provided the main market for these goods earlier, lost their territories to the British.

By the close of the 18th century, the Industrial Revolution was in full swing in Europe. New technology made possible the development of machines which raised workers' productivity and promoted the growth of large scale industrial enterprises. Products could now be manufactured more quickly and cheaply than before. The British factories now required large quantities of raw materials for production and at the same time they had to capture foreign markets for the manufactured goods. England developed its own textile industry and with that/ the dependence on Indian textiles came to an end.

Effect of the Industrial Revolution on the Textile Industry

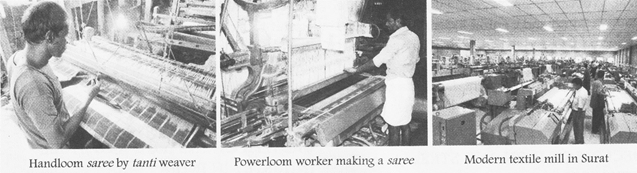

The Industrial Revolution is the name given to the movement in which machines changed the methods of goods production. The people of England began to use machines to make cloth and steam engines to run the machines. The textile industry, in particular, was transformed by industrialisation. Before mechanization and factory system of production; homemade textile products were mostly common. In the 1700s, a series of innovations led to ever- increasing productivity, while requiring less human energy. For example, around 1764, James Hargreaves invented the 'Spinning Jenny', a machine that enabled an individual to produce multiple spools of threads simultaneously. Another key innovation in textiles was, the powerloom, which mechanised the process of weaving cloth. It was developed in the 1780s in England by Edmund Cartwright.

EFFECT OF INDUSTRIAL REVOLUTION ON INDIA

The result of the Industrial Revolution was disastrous in case of India. Instead of buying finished textiles from India, the East India Company purchased raw cotton and exported it to England. India soon became a raw material producing country, supplying cotton and jute to the factories in Britain. Cotton was processed into finished cloth and exported back to India. The Indian markets were flooded with British cotton cloth. The British traders made massive profit through this two way trade. The machine made cloth of England began to replace the indigenous manufacturers. India's artisans were forced out of production. The local textile industry suffered heavy losses because the demand for Indian textiles went down. Moreover, the Company used its political resources to buy the best quality cotton from the Indian markets leaving no scope for the Indian weavers to produce good quality products. Gradually, the Indian handicraft and cottage industries declined. From an exporter of cotton textiles, India was converted into an importer of cotton textiles. Thus, the Industrial Revolution changed the face of India's trade and economy.

Matters became worse for the Indian craftsmen when the British government introduced the 'one way free trade'. Every country charges a tax or duty when goods are imported. The British abolished the duty on goods entering India. The British goods thus became cheaper and this ruined the domestic market for Indian goods. At the same time, the Indian goods going into Britain were taxed heavily making them more expensive. Consequently, even the foreign market for Indian goods was badly affected.

Q. why do you think the British introduced the 'one way free trade'?

Many weavers and spinners were in a miserable state as they no longer had any work to sustain themselves. There was no market for their hand-made goods. Many manufacturing units were shut down and the workers were left unemployed. The unemployed artisans had no option but to go back to villages and work as landless labourers. Thus, there was an increasing dependence on agriculture. This led to de- industrialisation of India?the traditional Indian handicraft industry was ruined completely.

However, weaving of some types of cloth continued because machines could not produce some special kinds of textiles. These were the intricate zari border sarees and brocades. These were worn by the rich. Also, the very coarse cloth could not be made by machines. Some towns now emerged as important weaving centres., e.g., Sholapur and Madura.

History Reveals

Lord Bentinck reported, "The misery of the weavers hardly finds a parallel in the history of commerce. The bones of the cotton weavers are bleaching the plains of India.

Textile Industry and the National Movement

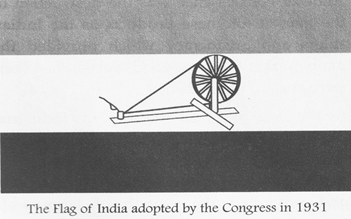

The swadeshi movement helped in the promotion of indigenous industries. Gandhiji was of the opinion that people should spin the charkha and weave khadi for their own use. He insisted that, people should boycott foreign clothes and wear khadi instead. He popularised the use of charkha.

The cotton textile industry made rapid progress in the second half of the 19th century. The Swadeshi movement gave further impetus to the Indian textile industry. When the First World War broke out, the British government could not get textiles from Britain. During this time, the Indian textile industries benefited immensely. The Indian mills got orders to produce textiles for military supply.

GROWTH OF THE TEXTILE INDUSTRY IN INDIA

The first textile factory in India was established near Calcutta in 1818. The first cotton spinning mill was established in Bombay in 1854. Bombay was the ideal place because it was in the region with black soil which was excellent for growing cotton. Thus, raw material could be easily secured. In 1861, a mill was established in Ahmedabad. Consequently, many mills came up in cities like Kanpur. In 1874, Jamshedji Tata founded the Central India Spinning, Weaving and Manufacturing Company at Nagpur.

This later became the most prominent mill in India, out producing all British-owned mills and becoming well-known for its quality. Tata went on to establish textile mills across much of India. Many of the weavers and spinners went to cities to find employment in these mills. After independence, the textile industry in India flourished and is a leading industry of the country today.

THE IRON AND STEEL INDUSTRY IN INDIA

India has been known for its iron and steel since ancient times. The famous rust free Iron Pillar at Delhi and the Iron Beam at Konark are examples of metallurgical skills of Indians. The 12th century Arab texts mention that, "The Hindus excelled in the manufacture of iron and it was impossible to find anything that could surpass the sharp edge of Indian steel". This was Wootz steel.

A TECHNOLOGY LOST IN TIME?THE 'WOOTZ STEEL'

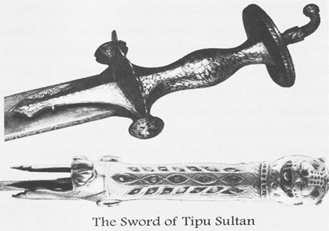

The sword of Tipu Sultan continues to evoke interest. He fought four wars with the British using his sword. His sword is very famous and it is made up of Wootz steel. It is known for its toughness and high carbon content. The sword had a very sharp edge with a flowing water pattern. This was because, it had very small carbon crystals in its content.

In 1799, after the defeat of Tipu Sultan and the fall n of Mysore, Francis Buchanan was asked by Lord Wellesley to survey South India. He write a book titled 'A Journey from Madras through the Countries of Mysore, Canara and Malabar'. He has written about the smelting furnaces of Mysore producing Wootz steel ingots that were used for making the finest swords. The process of making Wootz steel was forgotten in the subsequent years. This was because of the imports of iron and steel by the British government which replaced the steel made in smelting furnaces in Indian homes.

Wootz was an exceptional grade iron ore made in South and Central India as early as 300 B.C. Wootz is derived from the Kannada word 'ukku''. Made from high grade ore, it is believed to have originated in present day Telangana and Andhra Pradesh. It was used to make swords and daggers. Wootz ingots were traded to Persia.

DECLINE OF IRON AND STEEL FURNACES IN INDIA

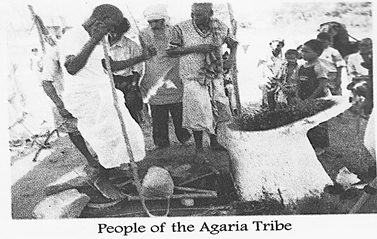

Iron smelting in India was done by villagers in furnaces made of clay and bricks. Locally found deposits of iron ore were used to make iron ingots. Many tribes also specialized in this. Traditionally, the Agaria tribes were iron-smelt workers and miners. The name Agaria is derived from the Hindi word 'aag' meaning 'fire', and from the association with the furnace used for smelting iron ore. They also call themselves Lohar (from the word 'loha', meaning iron).

However, there was a decline in iron smelting during the British rule. The furnaces were no longer used. This was due to a number of reasons. The British began to import iron and steel from Britian. This was used instead of the local steel for producing articles. Also, the forest laws of the British prevented the people from using forest produce. Without wood, iron ore and charcoal from the forests; the local ironsmiths could not smelt any iron. Mostly, they left this profession and took up other means to earn a livelihood.

Also, in places where the British did permit the local people to use forest product' they had to pay very high taxes. The poor smelters could then no longer afford to carry on with this occupation and sought other means of livelihood.

GROWTH OF THE IRON AND STEEL INDUSTRY IN INDIA

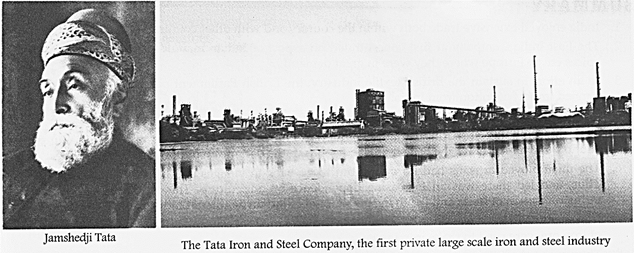

The British imported all steel products and made no effort to set up steel industry in India. India had plentiful resources which were not utilized. However, Jamshedji Tata was determined to set up an iron and steel industry. His son along with a British geologist surveyed the Chhattisgarh area to find an ideal location for the industry where good quality iron ore and other resources were available. With the help of the local tribes, they were able to locate rich deposits of iron ore. However, due to water shortage, the steel plant was not set up there.

Q. can you guess which tribes helped Tatas in searching iron deposites and establishing such a large private setup?

The Tata Iron and Steel Company was started in 1907 at Sakchi, near the confluence of the rivers Subamarekha and Kharkai in Jharkhand. Later, Sakchi was renamed as Jamshedpur. Geographically, Jamshedpur is the most conveniently situated iron and steel centre in the country.

Q. Why was Sakchi renamed as Jamshedpir?

TISCO was the first modem iron and steel plant in India. With modest beginning, by 1911, it had a substantial production and soon it became the largest single steel plant in the British Commonwealth. Initially, the British continued to import steel especially for the railway which required large quantities of it. However, the outbreak of the First World War proved beneficial for the industry.

The British were unable to import steel and became dependent on TISCO to meet its need of steel. By the time the war ended, TISCO established itself as a huge industry. The development of the iron and steel industry opened the doors to rapid industrial development in India.

Around the World

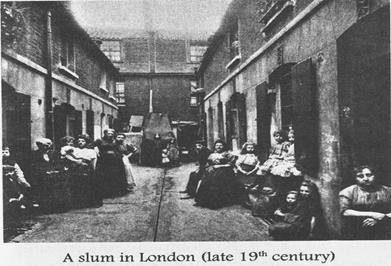

By the 1850s, there were many factories in England and large busy towns began to grow around them. Some of these towns became important industrial centres with rapidly expanding populations e.g., Leeds, Manchester, Birmingham and Liverpool. The factory owners were reaping huge profits but the workers were poorly paid. They lived in the dirty and crowded parts of the towns known as 'slums'. These were overcrowded and had unsanitary living conditions. Also, the new factories created pollution that contaminated both water supplies and air. The crime rate was also high. This was because people were so poor that they resorted to stealing to survive.

You need to login to perform this action.

You will be redirected in

3 sec