Utlization of Electrical Energy

Category : Railways

Utlization of Electrical Energy

In electrical engineering, utilization factor, is the ratio of the maximum load which could be drawn to the rated capacity of the system, this is closely related to the concept of Load factor The Load factor is the ratio of the load that a piece of equipment actually draws (time averaged) when it is in operation to the load it could draw (which we call full load).

ELECTRICAL DRIVE

Electrical drive system is widely used in large number of industrial and domestic applications like factories, transportation systems, textile mills, fans, pumps, motors, robots etc.

The main advantage of this concept is, the motion control is easily optimized with the help of drive. In very simple words, the systems which control the motion of the electrical machines, are known as electrical drives.

A typical drive system is assembled with a electric motor and a sophisticated control system that controls the rotation of the motor shaft.

Now days, this control can be done easily with the help of software. So, the controlling becomes more and more accurate and this concept of drive also provides the ease of use.

Drives are employed as prime movers for diesel or petrol engines, gas or steam turbines, hydraulic motors and electric motors.

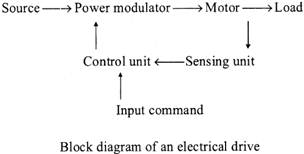

The very basic block diagram an electric drives is shown below.

The load in the figure represents various types of equipment’s which consist of electric motor, like fans, pumps, washing machines etc

CLASSIFICATION OF ELECTRIC DRIVES

The classification of electrical drives can be done depending upon the various components of the drive system. Now according to the design, the drives can be classified into three types such as single-motor drive group motor drive and multi motor drive.

The single motor types are the very basic type of drive which are mainly used in simple metal working, house hold appliances etc Group electric drives are used in modem industries because of various complexities. Multi motor drives are used in heavy industries or where multiple motoring units are required such as railway transport. If we divide from another point of view, these drives are of two types:

One classification point of view is how many motors (axis are operated from one device. There are one and multiple (axles) are operated electronic drives.

Electrical Drive System:

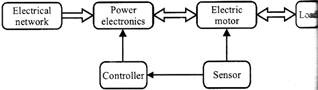

The main components of an electrical drive system can be seen in Figure below.

The thick arrows denoting the way of energy flow. Depending on the actual application there may be a two-way energy flow the load side.

Electromagnetic motors are also capable of the two-way energy flow, but for the power electronic devices this is not always possible especially for the older types.

ELECTRICAL MOTOR

The electrical motor is a device that has brought about one the biggest advancements in the fields of engineering technology ever since the invention of electricity.

A motor is nothing but an electro-mechanical device that converts electrical energy to mechanical energy.

There are different types of motor have been developed different specific purposes.

In simple words we can say a device that produces rotational force is a motor.

The very basic principal of functioning of an electrical motor lies on the fact that force is experienced in the direction perpendicular to magnetic field and the current, when field and current are made to interact with each other.

Classification or Types of Motor

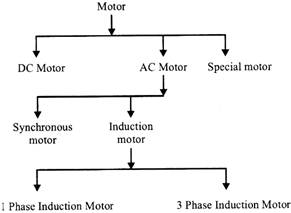

Electric motors are broadly classified into three categories as follows

The primary classification of motor or types of motor can be an tabulated as shown below,

DC Motors

DC motors have been used in industrial applications for years Coupled with a DC drive, DC motors provide very precise control

DC motors can be used with conveyors, elevators, extruders, marine applications, material handling, paper, plastics, rubber, steel, and textile applications, automobile, aircraft, and portable electronics, in speed control applications.

Advantages of DC motors

Disadvantages of DC motors

A.C. Motors

An AC motor is an electric motor driven by an alternating current (AC). The AC motor commonly consists of two basic parts, an outside stationary stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor attached to the output shaft producing a second rotating magnetic field. The rotor magnetic field may be produced by permanent magnets, reluctance saliency, or AC electrical windings.

As a result, motor manufactures have tried, over the last few decades, to perfect various types of a. c. motors suitable for all classes of industrial drives and for both single and three-phase

Advantages of AC motors

Its starting arrangement is simple especially for squirrel- cage type motor.

Disadvantages of AC motors

Special Electric Motors

The special electric motors are special purpose designs motors have been developed to solve a wide range of drive problems

The following types of special electric motors can be manufactured.

Difference Between Electric Motor and Drives

It is important to distinguish between motors and drives.

A motor is the mechanical or electrical device that generates the rotational or linear force used to power a machine. A drive is the electronic device that harnesses and controls the electrical energy sent to the motor.

The drive feeds electricity into the motor in varying amounts and at varying frequencies, thereby indirectly controlling the motor's speed and torque.

There are two types of drives:

(i) a standard inverter drive for controlling speed and torque only.

(ii) a servo drive for controlling speed and torque, as well as positioning machine components used in applications that require complex motion.

Together, a motor and drive form a "drive system."

ILLUMINATION

Illuminate means to shine light on a thing and to make it brighter and more visible is known as Illumination. The Illuminance (E) at any point on a plane perpendicular to the line joining the point and source is inversely proportional to the square of the distance between the source and plane.

\[E=\frac{I}{{{d}^{2}}}\]

Where, I is the luminous intensity in a given direction & d is the distance.

The Cosine Law of Illuminance

The illumination received on a surface is proportional to the cosine of the angle between the direction of the incident light rays and the normal to the surface at the point of incidence. This" is mainly due to the reduction of the projected area as the angle of incidence increases. Thus the point source Illuminance equation is:

\[E=\frac{{{I}_{\theta }}}{{{d}^{2}}}\,\,\cos \,\,\theta \]

Where\[{{I}_{\theta }}\]is the luminous intensity of the source in the direction of the illuminated point, 9 is the angle between the normal to the plane containing the illuminated point and the line joining the source to the illuminated point.

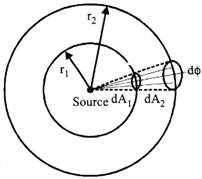

Inverse Square Law for Electric Illumination

The illumination upon a surface varies inversely as the square of the distance of the surface from the source. Thus if the illumination at a surface one meter from the source is X units, then the illumination at 2 meters will be X/4 at 3 meters will be X/9 and so on.

Strictly the inverse square law operates only when the light rays are from a point source and are incident normally upon the surface.

Thus illumination in lamberts/\[metr{{e}^{2}}\] on a normal place

= Candle power / (Distance in \[metre{{)}^{2}}\]

However, illumination from a uniform diffusing area such as indirectly lighted ceiling is independent of distance, provided the distance concerned is small in relation to the size of the source.

Types of Illumination or Lamps

The different types of Illumination or lamps include the following:

Incandescent Lamps

Incandescent bulbs are standard bulbs and many people are quite familiar with these bulbs. These incandescent bulbs are available in a broad range of sizes and voltages. An-incandesce bulb glows and produces heat when electricity passes through the tungsten filament present inside the bulb. The filament this bulb is placed either in a mixture of nitrogen gas or in vacuum. These bulbs are being gradually replaced by LEDs fluorescent lamps, and other service based new technologies-

The reason for this is that when this bulb is switched on, the sudden flow of current, energy and heat penetrate the thin area which in turn heat up the filament; once the filament heats up.' tends to break and burns out the bulb. Incandescent bulbs can last for 700 – 1000 hours and can also be used with a dimmer, Incandescent bulbs generate steady heat, which is quite good for house hold applications. Luminous efficiency of incandescent lamp is about 15 lumens per watt.

Compact Fluorescent Lamps

A compact fluorescent lamp is a modem type of light bulb that works like a fluorescent lamp. It contains mercury, which cause difficulties to its disposal. A CFL is designed to replace an Incandescent lamp. Generally, CFLs use less power, produce San amount of light and have long lifespan. Most of the compact fluorescent lamps consist of two or three tubular loop, Sometimes they even look quite similar to incandescent bulb These lamps cannot be used with dimmers, and usually they can last for 10,000 hours. Luminous efficiency of a compact fluorescent lamp is about 60 lumens per watt.

Light Emitting Diode

LED lamp is an electrical component that emits light through the movement of electrons in a semiconductor device. It lacks filament, uses less power and has a long lifespan. LEDs produce more light than incandescent lamps and help save energy in energy-conserving devices. LEDs are usually assembled into a light bulb to be used as a LED lighting system. These diodes can emit light of an intended color without the use of color filters.

The initial cost of a LED is generally high and these are used to build electronic projects.

High Intensity Discharge Lamps

Metal halide, mercury vapor, self-ballasted-mercury lamps high-pressure-sodium lamps all are high intensity discharge lamps. These lamps are specially designed with inner glass tubes that include tungsten electrodes with electrical arc. This inner glass tube is filled with both metals and gas. With the immunity of the self-ballasted lamps, auxiliary equipment (starters and ballasts) must be provided for proper operation of each bulb.

These lamps produce a large quantity of light compared to the fluorescent and incandescent lamps. High-intensity-discharge lamps are normally used when high levels of light are required over large areas which include outdoor activity areas, gymnasiums, large public areas, pathways, roadways and parking lots.

ELECTRICAL HEATING

Electric heating is any process in which electrical energy is converted to heat.

An electric heater is an electrical device that converts electric current to heat.

In other word, Electric heating means production of heat energy from electrical energy. That means production of heat by electricity

The heating element inside every electric heater is an electrical resistor, and works on the principle of Joule heating: An electric current passing through a resistor will convert that electrical energy into heat energy.

Most modern electric heating devices use Ni-chrome wire as the active element; the heating element, depicted on the right, uses Ni-chrome wire supported by ceramic insulators.

Electric heating is required for various daily domestic purposes like cooking, room heating, water heating, toasting breads, pressing cloths etc.

Electric heating is also essentially used in industrial application like, melting of metals, heat treatment processes, molding of glasses, baking of insulators, enamellings of copper wires, welding etc.

The main advantage of electric heating is that, the cost expenditure for heating purpose is quite low compared to other process of heating.

In addition to that there are several other advantages of electric heating

Methods of Electric Heating

There are different systems of electric heating used in domestic and industrial purposes. Each of the types of heating system involves its own method of electric heating. These heating methods can be categorized as,

Heating Effect of Electric Current

Whenever current passes through a conductor there would be a generation of heat due to ohmic loss in the conductor.

This is commonly known as heating effect of current. Since, we cannot use electric power directly, we need to convert it into another usable power, like heat, light, or mechanical power etc. When current flows through a conductor some loss occurs and this loss is almost inevitable, and more the resistance of the conductor, more the loss. This loss due to the electrical resistance of conductor is mainly responsible for the heating effect of current.

As some electric power is converted into heat energy, this phenomenon can be described by Joule's law, which states that,

\[H={{i}^{2}}.r.t,\] Where

H is the generated heat in calories

i is the current that is flowing through the wire and it is measured in amperes

r is the resistance of the conductor in ohm(Q)

t is the duration of current flowing in seconds.

ELECTRICAL WELDING

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In other words it is a process that is used to join metal to metal by using electricity to create heat enough to melt metal, and the melted metals when cool result in a binding of the metals.

They can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapor, or slag.

Classification of welding processes

There are about 35 different welding and brazing process and several soldering methods, in use by the industry today. There are various ways of classifying the welding for example, they may be classified on the basis of source of heat (flames, arc etc.) In general various welding processes are classified as follows.

ELECTROPLATING

Electroplating involves passing an electric current through a solution called an electrolyte. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply.

The electrodes and electrolyte are made from carefully chosen elements or compounds. When the electricity flows through the circuit they make, the electrolyte splits up and some of the metal atoms it contains are deposited in a thin layer on top of one of the electrodes-it becomes electroplated. All kinds of metals can be plated in this way, including gold, silver, tin, zinc, copper, cadmium, chromium, nickel, platinum, and lead.

Electroplating is very similar to electrolysis (using electricity to split up a chemical solution), which is the reverse of the process by which batteries produce electric currents.

All these things are examples of electrochemistry: chemical reactions caused by or producing electricity that give scientifically or industrially useful end-products.

You need to login to perform this action.

You will be redirected in

3 sec