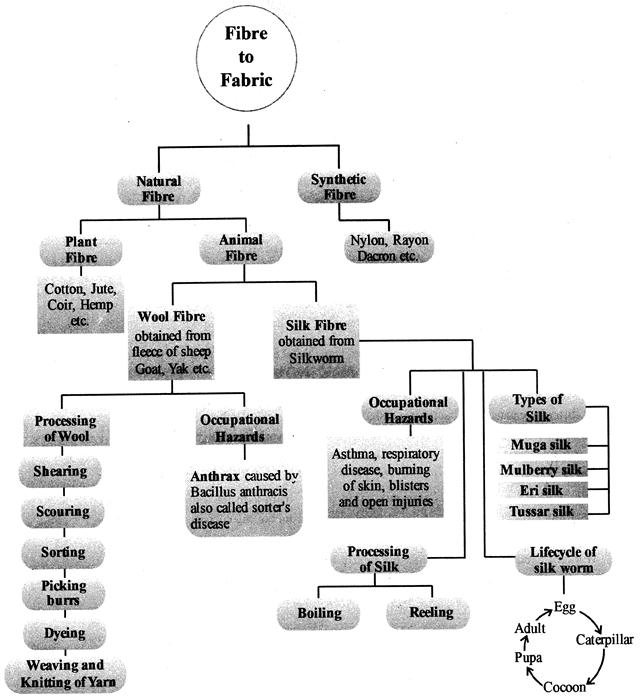

Fiber to Fabric

Category : 7th Class

Learning Objectives

Fibre are hair-like material that form the building blocks from which yam and fabric are made. Fibres obtained from plants and animals are called natural fibres. The history of fibres is as old as human civilization. Most clothing worn in the Stone Age was probably made from the skins of animals. It is also likely that some clothing was made by weaving grasses and other plant life.

You have leamt in previous class about type of clothing material, their development and types of fibres obtained from plants which includes Fabric like cotton, jute, coir etc. In this chapter you will leam about animal fibres. Wool and silk are two important fibres obtained from animals. These natural fibres are used to make a variety of fabrics. Wool is hair of animals like sheep, goat, rabbit, camel etc. Sweaters, socks, gloves, scarves, shawls and coats etc., are made from these hairs/fibres. Stuffing for furniture can be done from wool, and recycled wool can be utilized to make insulation and sound proofing. Wool also has a long history of being used in carpets and carpet padding. Silk is obtained from salivary secretion of silkworm. Besides clothing silk is also used in wall hangings, paintings, religious ornamentation, interior decoration, and to maintain religious records. Now lets leam more about these animal fibres and how these are converted into fabrics.

Do you know?

Natural fibres of animal origin are mostly protein fibres while those of plant source like cotton and jute are starch based.

WOOL

Wool is obtained from fleece of sheep and goat .It is also obtained from llama, alpaca, angora rabbit, yak etc. It is used in various ways to make woolen clothing, carpets, rugs and shelters.

Do you know?

Australia is the biggest grower of wool in the world.

Characteristics of Wool

Do you know?

Bharat Merino a breed of sheep was evolved at the central sheep and wool research institute, Rajasthan. This breed yield very fine wool used for clothing.

Sheep wool has an incredible natural protection from Ultra violet rays.

WOOL YIELDING ANIMALS

Sheep

Sheep has a thick coat of fleece on its body. A sheep's body has two types of fibres that form its fleece -the coarse beard hair and the fine soft under hair close to skin. The fine inner hairs are used to produce wool. There are different breeds of sheep in our country. Different kinds of sheep produce different quality of wool. The finest wool is obtained from the Merino, a breed of sheep originally from Spain.

Merino Sheep

Goat

Angora Goat - The angora goat is originally from the angora region in Turkey. The fibre obtained from the angora goat is called mohair.

Cashmere goat -These are found in higher plateaus of china, Mongolia and Tibet. The hairy skin of goat has a combination of fine hair and coarse hair.

Kashmiri goat - Wool obtained from Kashmir goat is soft and is used to weave fine quality shawls called Pashmina shawls.

Angora Goat

Camel

Bactrian camels of Siberia, Mongolia and China give us best quality of wool. Fabric obtained from camel’s hair is sometimes left in their original color due to its natural beauty. A male camel yields about 12kg to 15 kg wool while a female camel yields 6 kg to 8 kg of wool in a year.

Kashmiri goat

Alpaca, Llama and Vicuna are three important member of camel family that are found in south American continent and yield wool which are very fine, soft and lustrous.

Bactrian camel Alpaca Liama

Do you know?

Alpacas belonging to camel family produce wool in more than 22 different colors.

Do you know?

Vicunas are an endangered species so their fibre is rare and very expensive.

Yak

Yaks live in high mountain regions like Tibet and Ladakh. Their undercoat is soft that gives silky wool.

Angora rabbit

Angora rabbit is well known for its fine wool. These wool fibres are available in lesser amount and are expensive.

REARING AND BREEDING OF SHEEP

Rearing of Sheep

Rearing of sheep involves proper planning for shelter and taking care of its basic hygiene. Sheep are reared in many regions of our country including Jammu and Kashmir, Himachal Pradesh, Uttrakhand, Arunachal Pradesh, Sikkim and plains ofHaryana, Rajsthan, Punjab and Gujrat.

Their main food consist of grasses, leaves and grains. Sheep rearer also feed them with mixture of pulses, corn, jowar and oil cake.

Breeding of Sheeps

There are different breeds of sheep in our country. Some breeds of sheep possess only fine under hair. These breeds are produced by selecting the parents for obtaining special characteristics in their off springs, such as soft under hair. This process, in which parents are specially chosen to give birth to sheep having only soft under hair are called selective breeding.

Some breeds of Indian seep are:

|

S. No. |

Name of breed |

Quality of wool |

State where found |

|

1. |

Lohi |

Good quality wool |

Rajasthan, Punjab |

|

2. |

Rampur bushair |

Brown feece |

Uttar Pradesh, Himachal Pradesh |

|

3. |

Nali |

Carpet wool |

Rajasthan, Haryana, Punjab |

|

4. |

Bakharawal |

For woolen shawls |

Jammu and Kashmir |

|

5. |

Marwari |

Coarse wool |

Gujarat |

|

6. |

Patanwadi |

For hosiery |

Gujarat |

PROCESSING FIBRES INTO WOOL

The process, of removing fleece from the body of sheep is called shearing. The person who remove the fleece of sheep is called shearer. Shearing is done manually by clippers or pair of scissors. Machines are also used for shearing of sheep. Typically a sheep is sheared once in a year during spring. Shearing does not hurt the sheep just as it does not hurt us while getting a hair cut.

Do you know?

Jackie Howe holds the record for hand shearing sheep. He was able to shear 321 sheep in one day in 1892.

After shearing, wool is washed in hot water, detergent and alkali in tank to remove any grass, dirt or grease. It is then dried. This process is called scouring. Machines are used for scouring the fleece now a days.

Scouring is followed by sorting. The process of separating hairs of different texture is called sorting.

Do you know?

The largest wool producing country is Australia followed by new Zealand, South Africa, Uruguay, China and Argentina.

The small fluffy fibres are then picked out from the hair. These fluffy fibres are called burrs. These burrs can also be seen in sweaters. The fibres are again scoured and dried.

In grading, wool is grouped according to its length, colour, texture and ease of dyeing.

Do you know?

Wool is marketed world wide by international wool secretariat (IWS). It is located in United Kingdom. The wool mark logo indicates the purity of woolen

The fibres are dyed in various colors.

The fibres are straightened, combed and rolled into yam. These yams are wound to form balls of wool used for knitting or weaving woolen clothes.

Knitting of wool Woolmark logo

SILK

Silk is called the Queen of textiles. Silk is obtained from silkworms. The finest silk comes from the silkworms produced by the Bombyx mori moth. Silk is strong, shiny, lustrous fibre that is used to make fabrics. The rearing and management of silkworm for obtaining the silk is called sericulture. China and Japan together manufacture more than 50% of the world silk production. India and Italy are also significant silk producers.

Silk fiber and Fabric

Do you know?

Silk as a wearable fiber was first discovered by the Chinese emperor Xi Ling shi during 2,640 B.C. and its culture and weaving was a guarded secret for more than 2500 years by the Chinese. The production of silk in Europe began in 590 AD and around 300AD in India.

Characteristics of Silk

Do you know?

In India, about 90% mulberry silk comes form Karnataka, Andhra Pradesh and Namil nadu.

LIFE CYCLE OF SILKWORM

The life cycle of silkworm or caterpillar has four distinct stages. These are egg, caterpillar (larva), pupa and moth.

Laying of Eggs

The female silk moth lay 300 to 400 eggs at a time. The female dies almost immediately after laying the egg.

Caterpillar or Larvae

The larvae hatch in about 10 days. The larvae feed on mulberry leaves for 3 to 4 weeks. During feeding each larva shed its skin four times which is called molting?

Silkworms

Cocoon

After sometime larva stops eating, changes its color and climb up the twig. At this stage it is called pupa. The pupa starts spinning the cocoon. In cocoon stage caterpillar cover itself completely with silk fibres. The cocoon is then collected and processed.

Cocoons of silkworms

Do you know?

The cocoon is made of a single continuous thread of raw silk around 1 kilometer (2/3 of a mile) long.

Silk Moth

The pupae then develop into silk moths that emerge from the cocoon by breaking it, damaging the continuity of thread. Silk is obtained from undamaged cocoon. Some of the healthy moths are trapped and kept for breeding.

Complete life cycle of silkworm can be given as following:

Do you know?

About 5500 silkworms are required to produce 1 kg of silk.

Do you know?

Silk was such an important product from China that the trade route from Europe to China became known as the silk route.

PROCESSING OF SILK

The cocoons are collected and boiled in water to kill the pupae inside them. After boiling the thread of the cocoon is carefully removed. This process of collecting thread from cocoon is called reeling. This is done by using special machines and the resulting silk is called raw silk which can be dyed into various colors. The silk thread is now ready for weaving.

Boling of cocoon Reeling of Silk

Do you know?

Until World War I, bullet proof vests were also made form silk

Do you know?

Spiders make webs of silk. It is extremely strong, about five time stronger than steel, waterproof and stretchable. Scientists are studying spider silk in order to try and replicate it.

TYPES OF SILK

Mulberry silk, Tussar silk, Muga silk and Eri silk are four varieties of natural silk. Mulberry silkmoth is the most common silk moth. The silk fibres obtained from this moth are soft, lustrous and elastic.

HEALTH HAZARDS OF WOOL AND SILK INDUSTRY

CONCEPT MAP

You need to login to perform this action.

You will be redirected in

3 sec