Bioenergy

Category : 12th Class

The energy obtained from biological sources is called bioenergy. Bioenergy is the use of biomass (organic matter) to produce electricity, transportation fuels or chemicals. Bioenergy sources include agriculture and forestry residues and the organic components of municipal and industrial wastes. Fossil fuels (coal, petroleum and natural gas) is not included under bioenergy.

Only 0.2% of solar radiations reaching the earth is converted into biomass. This amount is about-10 times the energy produced from nonbiomass sources. Being a tropical country, India receives more solar radiations and therefore has high potential for biomass synthesis to meet the requirement of energy.

Bioenergy is obtained from following types of biological sources:

Animal energy : Animal energy is basically of two forms :

(1) Human muscle power (HMP) : It is the form of animal energy, which is used throughout the world in the form of physical work by human race like farmers in the field, women in house work and non agricultural labourers like artisans in wood work, gardeners, etc. A major part of the energy utilized today belongs to this type and it constitutes about 1/5th of the total generated electricity in India. Thus, it constitutes the significant part of energy used.

(2) Draught animal power (DAP) : Animals are domesticated not only for providing us with food, hides and bones but they are also used in agriculture and transport. These animals play an important role in villages. India has about 84 million of work animals; 70 million bullocks; 8 million buffaloes and one million each to horses and camels. In addition mules, donkeys, elephants and yaks are also used. 50 percent of the Indian farmers have holdings less than two acres each, as a result they cannot use tractors. More than 15 million animal-drawn carts are use in India. Carts have the advantage that they can be used on all types of roads in all terrains. The energy potential of DAP is enormous. Suppose if each animal generates 0.5 horse power then the installed capacity of animals comes about 42 million horse power or 30,500 MW. This value is almost equal to total electric power generation in India. Because of poor quality of animals and outmoded designs of carts and agricultural machinery, full potential of DAP has not been realised in India. Methods recommended to achieve this are :

(i) Improved breeds of draught animals.

(ii) Use of better carts.

(iii) Proper management of grazing lands and pastures.

(iv) Supply of nutritious fodder.

Biofuels and Biomass : They are fuels of biological origin. Biofuels are major source of energy. They are renewable and if used properly and efficiently they can solve the energy problems of developing countries.

Biomass is the term applied to all materials whose origin can be traced to photosynthesis. Biomass can be used to generate producer gas, to run water pumps for irrigation, to obtain alcohol, to replace petrol, to generate biogas for cooking and lighting and to generate electricity.

Ways of utilising biomass as fuel

|

Biomass |

Process |

Form / Source of energy produced |

|

Wood |

Direct burning, Gasification, Carbonisation, Pyrolysis, Hydrolysis, Fermentation and Synthesis. |

Heat, Producer gas, Charcoal gas, Oil and Charcoal, Methanol, Ethanol, |

|

Agro-industrial residues. |

Fermentation/Distillation, Anaerobic digestion. |

Ethanol., Biogas |

|

Petroleum and Oil producing plants |

Cracking and direct use. |

Petroleum products, Heating, Running engines. |

|

Energy cropping |

Fermentation/ Distillations. |

Ethanol. |

Wood : It is the renewable and most common source of energy in use since time immemorial. Wood which is used as source of energy is called fuel wood and about 2 billion people in world are dependent upon wood as source of fuel. Excessive use of wood as fuel has led to deforestation, soil erosion, loss in fertility of soil and hence deterioration of environment.

The consumption of fuel wood was estimated at 1.7 billion \[{{m}^{3}}\] in 1984 of which more than two third was consumed in Asia and Africa.

Characteristics of good fire wood

(1) It should be highly combustible and catch fire easily.

(2) It should have high calorific value and should be free of disagreeable odour.

(3) The fuel wood plants should be present every where.

(4) These should be easy to dry and should not split when burnt.

(5) Should be non-resinous in nature and smokeless.

Good fire woods and bad fire woods

|

Good fire-woods |

Bad fire-woods |

|

Acacia senegal (Gum Arabic) |

Pinus roxburghii (Chir Pine) |

|

Acacia nilotica (Kikar) |

Mangifera indica (Mango) |

|

Albizzia (Siris) |

Madhuca indica (Mahua) |

|

Azadirachta indica (Neem) |

Bauhinia racemosa (Kachnar) |

|

Quercus (Oak) |

Bombax (Red silk cotton) |

|

Casuarina equisetifolia (Jhau) |

Michelia excelsa (Champak) |

|

Adina cordifolia (yellow teak) Hopea (Dammar tree) Dalbergia sisso (Shisham) Prosopis (Jand) Anogeissus latifolia (Axle wood, Dhawra) Ceripos tagal (Goran) Gmelina arborea (Gumhar) Terminalia tomentosa (Asna) Syzygium cumini (Jambolana Jamun) |

|

The angiospermic wood (hard wood) is generally better than gymnospermic wood (soft wood). Soft wood produces intense heat but for shorter periods and hard wood gives uniform heat for longer periods. Bad fuel wood does not catch fire quickly, has low flame, low calorific value, gets burnt quickly, is full of smoke with offensive odour.

Due to increase in population, the demand of fuel wood is increasing day by day and this has led to fuel wood crises. In order to overcome fuel wood crisis, following methods have been suggested :

(1) To grow more fuel wood trees, i.e., energy plantations.

(2) Proper designing of wood stoves or chullahs in order to increase efficiency of these and hence to save energy loss.

(3) Electric cremation should be enhanced.

(4) Energy production from woods by different processes like carbonisation (Change of wood into carbon/charcoal by heating), gasification (change of wood into producer gas by passing steam over incandescent coke), pyrolysis (thermochemical conversion of wood into charcoal, pyroligneous acid (10% acetic acid), wood gas, wood tar, wood alcohol, etc.).

Energy plantations : Energy plantations mean to grow more trees for fuelwood. The uses of energy plantations are :

(1) Solar energy can be stored continuously.

(2) Minimum technology is required for raising the trees.

(3) They are ecologically safe, economical, renewable and sufficient manpower is available to raise them.

(4) Green plant's are the best source of renewable energy.

(5) They do not require new technologies and major input.

Mobilisation of land resources : To minimise the danger of loss of agricultural land for growing fuelwood, trees should be grown for fuelwood on :

(1) On farmer's own land where cultivation is not done.

(2) Village common lands

(3) Along both sides of road, canals and railway tracks

(4) On degraded forests and

(5) On wastelands

Over 30 million hectares of land is available in India for energy plantations, without affecting land under agricultural and industrial use.

Selection of suitable species : While selecting suitable species following criteria can be considered :

(1) The saplings should establish quickly and rapidly.

(2) The species should be preferably local and well adapted to local climatic and soil conditions.

(3) It should have high coppicing ability or regenerative potential. Coppicing means thick growth of branches from the stump after the aerial branches have been removed. Coppiced growth is faster as compared to the growth of new saplings because they have already established root system.

(4) The plant should be able to grow with minimum water and fertilizer requirement.

(5) The plant should draw minimum quantity of nutrients from soil.

(6) Plants should be able to improve the soil quality like sterilisation, correction of alkalinity or acidity etc.

(7) Plants should have the xerophytic character when grown under xeric conditions.

(8) Plants should be resistant to pests and diseases.

(9) Plants grown along both the sides of roads and railway tracks should be able to tolerate water logging.

Development of suitable agro-technology : Techniques of growing particular species in particular habitat must be carried out to get maximum yield. Cultivating grasses and fodder crops along with fuel wood species brings out maximum land use.

Producer gas : It is mixture of mainly \[CO,{{H}_{2}},{{O}_{2}}.\]Producer gas is produced due to incomplete combusion of coal and wood. With restricted supply of air, coal and wood is burnt. Mixture gas thus produced is passed through filter to remove shoot and ashes. Now the gas is passed through coolers to condense other waste residue. Now the gas is released for industrial use. This gas is free from pollution. Raw material for producer gas is easily available and can be produced at normal temperature. The gas produced is inflammable but otherwise costly and generates less power.

Agro-industrial residues : Some methods have been devised for bioconversion of agricultural residues, industrial waste materials and animal wastes into energy. This is very important in solving the environmental pollution problems. About 28 percent of population in the developing countries uses dung and crop residues as fuel for cooking food. Thus potential fertilizer of the agricultural fields is wasted in burning. The problem can be solved by using dung to produce gobar gas (biogas) and residue can be used as manure. The aerobic fermentation of dung yields fuel as well as fertilizer.

Biogas (Gobar gas) : Biogas is methane rich fuel gas produced by anaerobic breakdown and fermentation of biomass. Biogas consists of \[50-70%\,\,C{{H}_{4}}\](methane), \[30-40%\,\,C{{O}_{2}},\text{ }1%\,\,{{H}_{2}}S\]

and traces of \[{{H}_{2}},\,{{N}_{2}},\,{{O}_{2}}\] and \[CO.\] Calorific value of biogas is \[4,429\,\,kcal/{{m}^{3}}\,\,(23-28MJ/{{m}^{3}}),\] when its \[C{{H}_{4}}\] content is 50%.

Composition of biogas

|

S.No. |

Name of gas |

Chemical formula |

Percentage |

|

(1) |

Methane |

\[C{{H}_{4}}\] |

\[50-68%\] |

|

(2) |

Carbon dioxide |

\[C{{O}_{2}}\] |

\[2535%\] |

|

(3) |

Hydrogen |

\[{{H}_{2}}\] |

\[15%\] |

|

(4) |

Nitrogen |

\[{{N}_{2}}\] |

\[27%\] |

|

(5) |

Oxygen |

\[{{O}_{2}}\] |

\[00.1%\] |

|

(6) |

Hydrogen sulphide |

\[{{H}_{2}}S\] |

Rare |

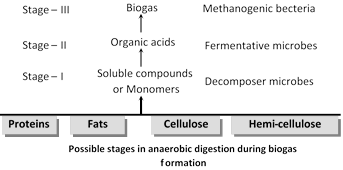

Biogas generation is a three stage anaerobic digestion of animal and other organic wastes.

First stage : The facultative anaerobic micro-organisms breakdown the polymers into soluble monomers with the help of enzymatic hydrolysis. The complex carbohydrates such as cellulose and hemicellulose are degraded by celluloytic enzymes. Proteins are broken by proteolytic enzymes and lipids by lipolytic enzymes. Lignin cannot be broken down by micro-organisms, so it remains as residue along with inorganic salts.

Second stage : Here the monomers become the substrate for micro-organisms. These are then converted into organic acids.

Third stage : In this stage soluble organic acids (acetic acid) are formed for the substrates of the last stage. Finally methanogenic anaerobic bacteria (e.g., Methanobacterium, Methanobacillus, Methanosarcina and Methanococcus) produce methane (biogas).

Biogas plants : Biogas (gobar gas) generation has been taken up in India on a large scale. One such plant is already existing at Okhla near New Delhi which generates a total of about 0.6 million cubic feet of gas per day. About 1.95 lakh biogas plants were set up during 1985-86 under the National Biogas Development Programe.

Important substrates in biogas production : Animal wastes like dung of cattle, urine and slaughter house wastes; agroindustrial wastes like oil cakes, sugar industry wastes, wastes from fruits and vegetables processing; agricultural or crop residues; human wastes (night soil); urban solid wastes and also aquatic plants like Eichhorina (water hyacinth), Wolffia, Hydrilla, Salvinia, Azolla and algae, etc.

In biogas production, water content is maintained at 90% at which most methanogenic bacteria are active.

The biogas so produced can be used for different purposes, can be efficiently used and stored easily. Further pathogens of faecal matter can be reduced (sanitation) and thus disease cycles are broken.

Energy cropping and petroplants : These are renewable resources of energy. Growing of crops from which alcohol and other energy fuels can be produced, constitute energy cropping. Important plants of energy cropping (i.e., energy crops) are :

(a) Saccharum officinarum (Sugarcane)

(b) Beta vulgaris (Beet root or Chukandar)

(c) Solanum tuberosum (Potato)

(d) Zea mays (Maize)

(e) Manihot glaziovii (Tapioca)

These plants are efficient users of solar energy. These plants can be easily changed into ethanol (ethyl alcohol). In Brazil, ethanol fuel is used in automobiles (95% alcohol), where as in USA, 85-90% petrol is mixed with 10- 15% alcohol to form a new fuel called gasohol, which is used as fuel in automobiles. But slight modification is required in conventional engines to use these new fuels, i.e., ethanol and gasohol.

Petroplants or Petrocrops : Latex of some plants containing long chain hydrocarbons is considered to be a good substitute for liquid fuels or petroleum. Such plants having large amount of latex with long chain hydrocarbons are called petroplants. Cultivation of petroplants is also a part of energy-cropping. Cultivation of these petrocrops was first of all done by Italians in Ethiopia about fifty years back, although actual credit for identifying the petrocrops goes to Dr. Melvin Calvin.

Dr. Calvin was first to identity few petroleum plants whose products can be used in place of petrol and oil. Most of such plants belong to families asclepiadaceae, euphorbiaceae and apocynaceae. These plants are able to convert a substantial amount of photosynthates into latex.

Latex contains long chained liquid hydrocarbons. These can be used directly or broken to hydrocarbons of chain length similar to the ones present in petrol.

Their hydrocarbon contents can be increased by genetic manipulations (genetic engineering). But commercial production of petroleum or liquid fuel alternative (through petroplants) is in early stage.

Most common petrocrops are :

(a) Euphorbia antisyphilitica

(b) E. caudicifolia

(c) E. lathyris (Gasoline tree)

(d) E. royleana

(e) Calotropis procera

(f) Copaifera langsdorfii (A Brazilian tree and its sap is a good alternative for diesel. About 3 litres of sap per month is produced per tree, which can be filled directly in fuel tank of diesel engine automobile).

(g) Cryptostegia grandiflora

(h) Pittosporum resiniferum (Petroleum nut)

The use of these petroplants may reduce the pressure on liquid fuel or petroleum.

You need to login to perform this action.

You will be redirected in

3 sec